Fire service historian and author

Roger Mardon

www.romar.org.uk

© Copyright Roger Mardon

www.romar.org.uk

All rights reserved

Previous

Next

The HydroSub 150 pump is the second in a range of four, the HydroSub 60, 150, 450 and 900. Shropshire Fire & Rescue Service has the 60 and 150 models.

The pump itself, Type HFS-

The diesel-

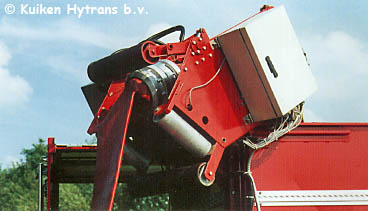

Each prime mover carries one Duo container, which is a demountable platform designed to carry two HydroSub 150 pump units, or two hose boxes, or one of each. The DC6500 model selected for the New Dimension pumping sets has a double cabinet at the front end providing compartments, with access from doors on each side, for portable water supply equipment. A top compartment houses a hose recovery unit and allows recovery operation from either side.

The hose boxes each carry 1,000m of flaked and coupled 150mm hose. Used with HFS portable water supply equipment, this large diameter hose can be used to create networks of thousands of metres.

The HRU-

A considerable amount of hardware (gate valves, Y-

The composition of the New Dimension pumping sets provides for one Duo demountable container to carry a pump, one hose recovery unit and one hose box, while the second container carries one hose recovery unit and two hose boxes. One prime mover is issued with each HVPU, i.e. one PM for each two Duo containers.

High volume pumping units have been used at serious fires, notably the Buncefield

oil depot explosion and fire in Hertfordshire on 11 December 2005, and in major flooding

incidents such as occurred in Carlisle in January 2005. Nine high volume pumps were

then deployed from the Fire Service College at Moreton-

Delivery of the high volume pumping units was completed in 2006. 48 units are deployed on a risk assessed basis as shown in the following table and two are kept as strategic reserves.

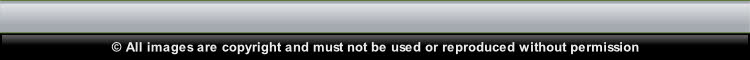

The contract for the supply of high volume pumping units (HVPUs) was awarded to Kuiken Hytrans b.v. of Lemmer, Netherlands. This company had already provided Shropshire Fire & Rescue Service with two of its HydroSub pumps. The Government has bought 50 Hytrans Fire System (HFS) pumping sets.

Each pumping set comprises

- One HydroSub 150 pump unit, consisting of a diesel-

hydraulic power unit and portable floating submersible pump - Three hose boxes, each containing 1km of 150mm (6in) hose

- Two hose recovery units

- Two 6.5m Duo containers with double equipment cabinet

|

Region |

Fire & Rescue Service |

Number of HVPUs |

|

London |

London |

6 |

|

South- |

Berkshire |

1 |

|

Buckinghamshire |

0 | |

|

East Sussex |

1 | |

|

Hampshire |

1 | |

|

Isle of Wight |

1 | |

|

Kent |

1 | |

|

Oxfordshire |

1 | |

|

Surrey |

1 | |

|

West Sussex |

0 | |

|

South West |

Avon |

1 |

|

Cornwall |

1 | |

|

Devon & Somerset |

2 | |

|

Dorset |

1 | |

|

Gloucestershire |

1 | |

|

Wiltshire |

0 | |

|

East of England |

Bedfordshire & Luton |

0 |

|

Cambridgeshire |

1 | |

|

Essex |

0 | |

|

Hertfordshire |

1 | |

|

Norfolk |

1 | |

|

Suffolk |

0 | |

|

East Midlands |

Derbyshire |

1 |

|

Leicestershire |

0 | |

|

Lincolnshire |

1 | |

|

Northamptonshire |

1 | |

|

Nottinghamshire |

1 | |

|

West Midlands |

Hereford & Worcester |

1 |

|

Shropshire |

1 | |

|

Staffordshire |

1 | |

|

Warwickshire |

1 | |

|

West Midlands |

1 | |

|

Yorkshire & Humberside |

Humberside |

1 |

|

North Yorkshire |

2 | |

|

South Yorkshire |

1 | |

|

West Yorkshire |

1 | |

|

North East |

Cleveland |

0 |

|

Durham & Darlington |

1 | |

|

Northumberland |

1 | |

|

Tyne & Wear |

0 | |

|

North West |

Cheshire |

1 |

|

Cumbria |

1 | |

|

Greater Manchester |

2 | |

|

Lancashire |

1 | |

|

Merseyside |

1 | |

|

Wales |

Mid & West Wales |

2 |

|

North Wales |

1 | |

|

South Wales |

1 | |

|

Strategic reserves |

|

2 |

The HFS-

The HydroSub 150 diesel-

For a layman's account of how an HVPU works in practice see High Volume Pumping Unit in Action.

High volume pumping units

Back to top